Jumping Into Manufacturing

As the team moves into the new semester, the manufacturing of FK08 begins. Each subsystem has jumped full force into the process to ensure the completion of this year's car.

New Faces and Design Progress

As Formula Kentucky has been shifting focus to the FK08 build cycle, the team welcomes new faces to every subsystem and finds itself deep in the design process.

Building Momentum Toward Competition Season

With competition just around the corner, the Formula Kentucky team is putting in the work to bring FK07 to life. Every subsystem is making strong progress toward May.

Transitioning from FK06 to FK07

After one of our best competitions yet at FSAE Michigan, we’re shifting gears toward FK07 with fresh designs, big goals, and a summer full of testing and innovation.

On Track with CKR & SCCA

From weekend autocross to Formula SAE, our members take their love for performance driving beyond the workshop. See how CKR and the UK’s collaboration helped us sharpen our skills on and off the track.

Inside the Build: The Journey of FK06

After months of design and planning, the team has officially begun manufacturing FK06, bringing together innovation, precision, and teamwork as we prepare for competition in May.

Fueling Passion Beyond the Workshop

Our members took to the track with CKR-SCCA to refine their driving skills, strengthen teamwork, and bring real-world performance experience back to the garage.

Setting the Stage for Formula Kentucky’s Growth

FK04 delivered standout results at FSAE Michigan 2022, including two top-three finishes and record improvements, paving the way for stronger designs and competition readiness.

Manufacturing Progress and Team Growth

As work on FK04 accelerated, new members joined every subsystem, sponsors shared feedback, and our team united to push the car closer to its most reliable build yet.

February 2025 Newsletter

Dear Supporters and Alumni of Formula Kentucky,

As we begin our spring semester the team is working hard on the manufacturing process to get the car ready for competition in May. Across the board, the subsystems have been putting in a lot of hard work and time as we begin to approach the testing period. As always we are very grateful to all of our sponsors who make this possible. We are excited to see the car come together and we can't wait to see the FK07 in its final form. As always thank you for your support!

Chassis

Chassis received the frame from VR3, who notch bends and cuts the tube frame to save hours of work in the shop. The frame was then laid out in the jig and tacked together before the entire welding process began. The welding of the frame was finished right before Christmas break. Currently, Chassis has begun placing all other needed tabs to install various components in the car. Other projects are awaiting parts arrival and will be built and installed once they arrive.

Aerodynamics

Since October, Aerodynamics has constructed the foam molds using the Shopbot machine to create the shapes for the carbon fiber layups. These were completed in the middle of January and will go through post-processing before being mounted to the car. They have also completed their first resin infusion layup since 2022 on the first of the two side pods. The team is in the process of designing livery ideas for the car including one that will mimic the DeLorean from Back to the Future.

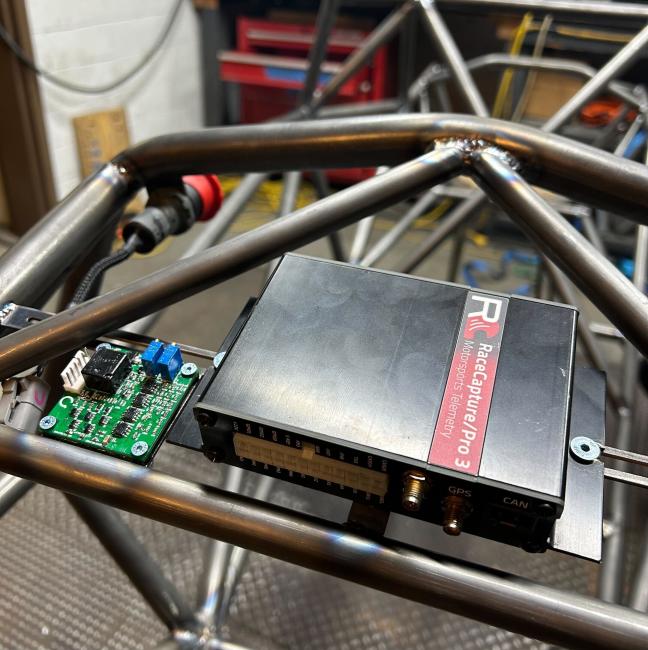

Electronics

Electronics has been working on developing the wiring harness, specifically with integrating the new telemetry system. Thanks to the Bosch Motorsports sponsorship the team has gotten their C70 datalogger along with three WinDarab seats, which has been used to make great strides in data collection and data analytics. Moving into manufacturing, they are looking forward to fabricating the main wiring harness as well as the breakout harness for the C70. The plan for the breakout harness is to make it completely motorsport spec, which will make it extremely durable and useful for years to come.

Powertrain

Since October, the Powertrain subsystem has been spending their time tearing down the engine from FK06 and refreshing the engine for FK07. They have been working on the installation of the radiator as well as the installation of the motor mount. There has also been finalization work on the oil pan gasket. Looking towards the future there has been work done on development for projects including an external fuel pump setup.

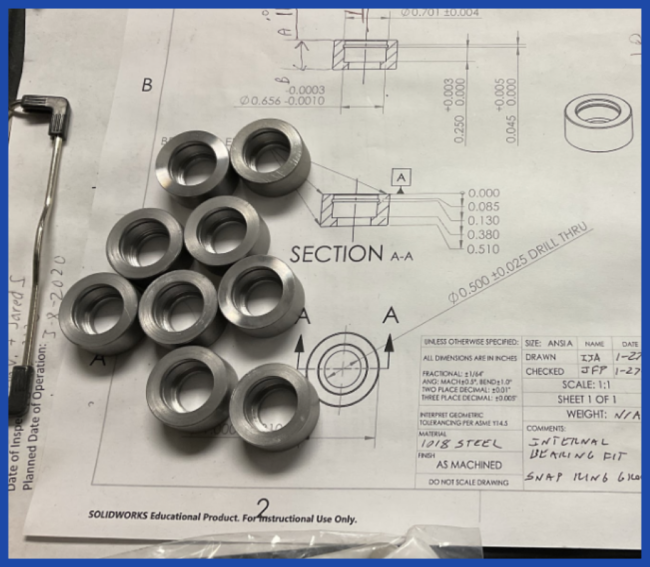

Suspension

Since October, Suspension has been hard at work getting various parts machined for assembly. This includes such parts as the spherical bearing housing shown in the picture. Right now all of those parts are coming together and the entire suspension will begin to be built in the upcoming weeks.

June 2024 Newsletter

Dear Supporters and Alumni of Formula Kentucky,

About two months ago in early May the team headed up to Michigan to compete in FSAEs annual event. With one of our strongest placements ever we thought it would be fun to ask all the subsystems how their comp was, and what they are planning for the summer.

The team is ready to transition from FK06 to FK07 over the summer and we have some very interesting new designs already being worked on for each subsystem. As always thank you for your support!

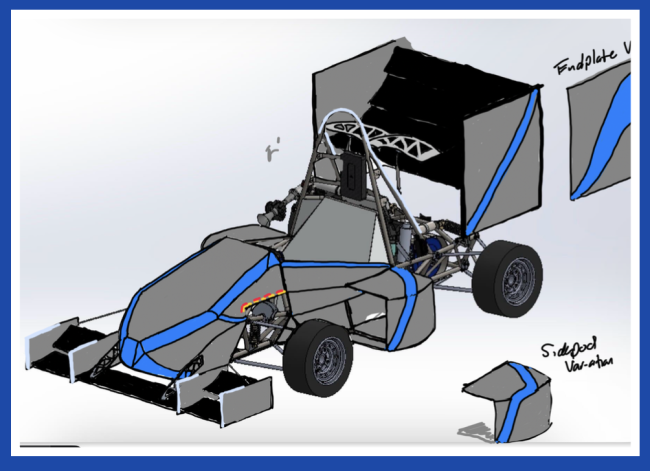

Aerodynamics

Aerodynamics lead Pierce said that they did really well at comp after some minor setbacks with technical inspection, their parts took impact with several cones and survived, proving the durability of the components. This summer they intend on testing different ducting for sidepods to aid in airflow to the radiator and engine. They also plan to test a front and rear wing to see how effective an aero package would be and if we should invest resources into designing one for FK07. Aero has been working very hard on research and simulations so we can't wait to see what they do for design in the fall.

Chassis

The Chassis subsystem and all of their other projects did very well at comp, only having a few minor issues. They faced adversity in tech inspection having issues with the fitment of the firewall, steering shafts, and having to pull out a foam pad in the headrest. The chassis scored well in judging, with the judges liking the pre manufacturing analysis on the chassis, like tests for torsional stiffness. The chassis lead Jason noted the summer plans going forward for the next car will be to keep the subsystem as similar as possible to last year and not make too many changes. “All of our components worked out very well and all we will be doing is slightly tweaking them.” The frame Is currently being remade with a few adjustments to tube sizing and the geometry of the roll bar and they will soon start on various other components.

Electronics

For FK07, the Electronics Subsystem had some outstanding results at comp. While the new Electronics lead Julian said they ran into a few issues they were able to resolve with some quick thinking, and overall they made some huge advancements. Electronics made it through ETC Tech for the first time with no issues this year and made a working Electronic Shifting System controlled by paddle shifters as well as made improvements in all other aspects like data collection. The plan for the summer is to iron out a few bugs here and there and improve the drivability and performance of our two new Electronically Controlled Systems.

Powertrain

Powertrain went through a very eventful May during this year's 2024 Michigan FSAE Competition. The subsystem certainly had its challenges during comp: from fuel leaks, trouble in tech inspection, drivetrain failures, to cooling failures. However in the end each challenge was overcome in route to having the highest design score on the team and successfully finishing endurance for the first time in five years. Powertrain’s new lead David said the goal for powertrain so far at the beginning of the FK07 build cycle is to continue their momentum from comp and continue to advance their projects. So far during the summer they have begun research and planning on a new dry sump system, titanium headers, and updates to the cooling system to name a few.

Suspension

During competition, the suspension subsystem's primary task was tuning the car based on track conditions. Depending on how wet the track was, temperature, and the driving event, they needed to change things like tire pressure, tire type, and shock settings to improve the car's overall performance. Over the summer, they plan to test an anti-roll-bar (ARB), which provides another dimension of adjustment for suspension. They also plan on adding shock potentiometers to the car over the summer, to track how far the shocks compress during operation. With former Suspension lead Peter becoming our new team captain we are excited to see how the new Suspension lead, Issac, tweaks last year's design and improves the car.

FK07 Design Updates

Lastly, some design updates from our Engineering Manager Catie. “FK07 design is in full effect! All subsystems are currently working on new designs, research, and validation for all our projects. Testing is being conducted most weekends to either validate designs we are keeping, or to aid in getting data for our new ideas and designs. We will continue to test throughout the rest of summer to grab new data as we carry on with the design and validation process.”

Once again thanks for all the support and we are ready to start the year off strong! See you in the Fall 2024 Newsletter!

Formula Kentucky and SCCA

Formula Kentucky is known for its dedication to a singular project; designing, manufacturing, and racing an open-wheeled style race car. Most of our members join for either their passion for cars and automotive racing, or to better their engineering skills. Within the team lies a few of our members who participate in SCCA events so they can have some friendly competition on the weekends.

CKR’s support in our program has been one of the most beneficial to the team as it allows us to utilize a local controlled space to refine our drivers either in their own car or in our FSAE car. We are excited to announce that UK and CKRSCCA will be hosting another joint venture at the University of Kentucky’s Orange Lot. This event will be on the 16th of June, so we hope to see you all there!

We are so glad that CKR is one of our team’s sponsors and we can't wait for what next year holds for both of our programs. We would like to highlight our members who participate in SCCA, especially since one of our team sponsors is CKRSCCA! Read their stories below!

Brody Brown: 2017 BMW M4

Photo Credits: Jack Delligatti

“SCCA has really helped me to develop an understanding of my car. As I started shortly after purchasing my car and having never driven a rear-wheel drive car with that much power, it helped me adjust in a safe environment. Autocross is one of those things that is perfect for learning how to properly drive a car, make you comfortable in situations that require fast reflexes, and safely fills the need for speed that so many of us have. The best part is all of these things are done without putting the car or people in particularly risky situations. Overall, I did ok, but I take it as an absolute win, as I got a ton of great pointers from better drivers that will help me continue to improve.” -Brody Brown

Ethan Kammer: Miata Kart #2 (Co-driving with Jude W.)

Photo Credits: Jack Delligatti

“SCCA is a great way for people to not only get to drive their own cars in a closed environment. They get the opportunity to learn driving skills that not only make you a faster driver but a safer driver on the road since you’ll be more prepared for the scary unexpected situations. I was driving the Miata kart with Jude for this event but I normally run a 2001 Miata that is currently getting some upgrades. This event though I placed 23 out of 97 in raw overall time.” -Ethan Kammer

Kammer while also driving his own personal vehicle has been one of the most consistent and fastest drivers of our FSAE vehicle where CKR’s impact on his driving has helped him refine his attention to detail no matter the vehicles he's in.

Jude Ward: Miata Kart #22

Photo Credits: Kenta Goto (@atnekjp)

“CKRSCCA has been a crucial part of my development as a driver. From driving my personal vehicle to our FSAE car, the skills that I have gained both on and off the course have been instrumental in what you could call my ‘driving career.’ From learning basic vehicle dynamics and setup to analyzing competitive course layouts, CKR has been nothing short of challenging each time I go out. And that’s what keeps me returning; the challenges of the course, the challenges of the car, and most of all, the challenges of driving against the people I get to see. Whether it’s my home class of CAM-T, or kicking it in F Street, there’s always something fun to chase at CKRSCCA!” - Jude Ward

Jude is rounding out his last semester as our acting Team Captain and we hope to continue to see him and other members at CKR's events in the future!

John Psyck: Gray Focus ST #02/102 (Co-driving w/ Colton C.)

Photo Credits: Kenta Goto (@atnekjp)

“SCCA helps me to improve my skills as a driver through both the main autocross events, as well as our region's driving school days with their instructors. It has also helped me gain a better understanding of the ‘feeling’ of vehicle dynamics and suspension tuning, as I am able to change the setup of my car each event and then feel the difference. This has helped me in both Formula SAE and in my current motorsports career."

At the latest fun event, my co-driver and I had a lower finish but we were also focused on feeling the brand new suspension out and shaking down the car so I was very happy with everything just staying together!” - John Psyck

John has always had a keen sense for helping setup the FSAE car, and it's no surprise here that like many other drivers, finding the time on track and figuring out how the car feels with a slew of upgrades present a learning curve every time!

Alex Kogos: 2003 Mitsubishi Lancer Evolution

Photo Credits: Kenta Goto (@atnekjp)

“SCCA helps me by allowing me to push my car to the limit without risking others on the road. I am able to get in sync with how my car reacts to certain environments and how different adjustments I make to it make a difference in handling. A large part of racing is being in tune with your car so the driver is ready for anything when on the track. It also helps the driver realize when something is wrong with the car by feeling how it starts reacting differently to the inputs you give it. I did very well at the latest autocross event. In terms of overall positions I did not do anything impressive, but seeing that this is only my 4th event, I improved greatly on my times and am getting really in tune with how my personal car drives. This skill translates to some degree to any car driving, including the Formula car, which I plan on utilizing in testing in the near future.” -Alex Kogos

Kogos has been on the team for only a year but has jumped into the deep end and hasn’t come up to breathe yet! We hope to see him and many more members strive to excel on the team and hone in their skills both on and off the track!

FK06 February Newsletter

Dear Supporters and Alumni of Formula Kentucky,

Over the last four months, the team has been working hard to revise the design and start fabrication for FK06! We’re looking forward to seeing the car come together in a few short months and starting to begin testing and data collection for competition in May! The team has transitioned from ordering materials and components to starting the manufacturing process. We are excited to continue hands-on work on FK06 and want to thank you for your support throughout this process, and cannot wait to keep you updated.

Aerodynamics

Aero has been hard at work over the last couple months! At the end of fall semester and the beginning of spring, Aero used the ShopBot to cut foam mold sections for their carbon fiber layups. The aero team used Inventor to create toolpaths for the ShopBot based on the contours of each individual part profile. These sections were put together with screws and body filler, or bondo, to hold the layers of foam in one cohesive shape. The seams are being sanded to ensure a smooth finish; smooth finishes are important as they can affect the final part’s surface finish as well as aerodynamic performance. They have also gotten some advice on Aircraft fabric from sponsor Bob Jones (Ragwingst) hat we’re using for our body panels. This fabric will help aero save 6-7 pounds total, as well as contribute to a smoother overall surface finish that will help with drag.

Aero has consistently been putting in 100+ hour weeks to get all of their parts prepped and ready for their first lay ups. They will have the part covered in a “release film” that will allow for the carbon layups to remove easier from the foam molds seen below. The carbon will be layered over the foam molds then painted with resin that will harden and turn it into the carbon parts for the car!

Pictured: Floor and nose cone molds

Business

Business has been hard at work on improving the team’s media and outreach. The website has been updated and newly redone to reflect the new vehicles and updated team information. The team instagram has been revived and posts are being drafted for sponsors and major updates with the car (follow us @FormulaKentucky if you dont already!). New business cards have been designed and are ready to be printed and distributed for upcoming new recruitments coming in the Fall of 2024. This year’s team shirt, Nike polo and Carhartt hoodies have been designed, and a clothing order has been sent out to keep the team looking professional and ready for competition (polo pictured polo).

Business has also teamed up with Aero to design a new livery for the car and the trailer. We are excited to announce that in addition to the generous Donations of Stan and Karen Pgiman, world renown motorsports sponsor and oil company Valvoline has become one of our newest title sponsors! “We appreciate the opportunities that all sponsors give to us as a student organization and we hope to impress them all with our best car yet, FK06!” -Jude Ward, Team Captain

Pictured: Engineering, Ashley Vanover and Team Captain, Jude Ward

Chassis

Chassis has begun their first of many manufacturing phases on the new car. The jig, which holds the tubes in place for welding, has been successfully water jetted and properly aligned with a laser alignment tool. Post jig assembly, the tubes of the chassis were put into the jig with custom 3D printed inserts to properly secure and align the chassis tubing into the jig. Welding of the chassis then took place by team member John Psyck who helped tremendously in the assembly process. Upon completion of the tabs being placed by all subsystems, the chassis will be sanded and painted a blue base coat with silver metallic flake as a second top coat. We hope that with the new additions of the custom livery and chassis paintwork that FK06 will be not only the best performing car, but also the most appealing too!

Chassis has also been hard at work with their other pictures like the completely carbon fiber steering wheel, seen below, as well as the newly redesigned two-pedal pedal box, driver firewall and headrest, and steering components. With more parts coming from future waterjet operations, chassis is on the way to having a full line-up of projects ready for the car!

.

Pictured in both: FK06 Chassis

Electronics

Our new intake restrictor, throttle body and velocity stack have all arrived and been assembled! This is the culmination of our summer testing, and was made possible by Toyota’s TiLT lab! One new development is our rifled restrictor section- something we hope to test with a flow bench to compare to a standard restrictor. We’re excited to finally take the plunge into more electrical controls on FK06, and the throttle and electric shifter are shaping up to be a killer combo.

With the chassis complete, we have begun placing our electrical components and respective tabs onto the car! Pictured is our data acquisition unit, courtesy of AutoSportLabs, as well as our BSPD and driver kill switches- both critical safety devices for our car. Now that we have a chassis, we are hoping to place all of our components quickly and begin finishing the rear section of our primary wiring harness!

“Thank you to everyone from electronics for your hard work over the last couple months.” -John Psyck, Electronics Lead

Pictured: Electronics hardware mount

Powertrain

Powertrain has been hard at work using the data they collected over the fall to start manufacturing. After extensive research and testing on the cooling system of the car, Powertrain came to the decision to utilize a smaller side mounted radiator. They also decided on a better sized external oil cooler. Both the radiator and the external oil cooler are mounted within the side pods to help direct air flow. This new design update will help with air flow through the radiator, which was previously mounted in the rear of the car.

Powertrain also developed a block off plate which will remove the need for the OEM oil heat exchanger. The OEM oil heat exchanger sat too close to the headers behind the firewall. The design of the intake is also being updated by moving the intake arm to the side to place the heavy electronic throttle body lower on the car. Lexmark, a long time sponsor and supporter of the team, is printing the plenum and arm. Cone Engineering, another supporter, is supplying some of the header components for the exhaust. The muffler from FKO5 is going to be recycled for the new car with some adaptations such as a different silencer and new baffles. The drivetrain is going through extensive updating with a larger rear sprocket, a hand-operated clutch, electronic shifting, and a newly integrated electronic throttle body.

The engine went through inspection and passed with flying colors. There were no areas of concern found with FK05’s engine and is set to be placed in FK06 on the next build cycle. With hard work and collaboration with the other subsystems, Powertrain is on its way to making FK06 unstoppable.

Suspension

Suspension has been working hard over the past couple months to meet their deadlines and have the car ready to run by April. Currently they are waiting on a machined components order to come in. Once they get their components they will be able to start the brunt of manufacturing work. In the interim, they have spent a lot of time preparing for the orders to come in, including creating jigs that help place and weld on mounts and Control Arms. They also removed old tires and placed them on our new tires.

We are hopeful they will have almost all of the machined components in by the end of the month, which should have them on track to meet the April 1st deadline. “Shout out to our sponsors for being so willing and generous with their time and money to do the machining on our uprights, spindles, and other smaller suspension components.” - Peter Szalay, Suspension Lead.

Formula Kentucky and SCCA

Formula Kentucky is known for its dedication to a singular project; designing, manufacturing, and racing an open-wheeled style race car. Most of our members join for either their passion for cars and automotive racing, or to better their engineering skills. Within the team lies a few of our members who participate in SCCA events so they can have some friendly competition on the weekends. We would like to highlight our members who participate in SCCA, especially since one of our team sponsors is CKRSCCA! Read their stories below.

Mike Snowden: 1997 Mazda Miata

He's had the Miata for several years and in that time has swapped in a ‘03 VVT Miata engine that’s tuned for E85 fuel using an aftermarket ECU. All the grip comes from Miata-specific Xidas suspension and 275 Hoosier slicks on wide wheels. Aside from that, the rest of the major modifications include a custom front splitter and rear spoiler, a racing seat, seat harnesses, and a roll bar.

Mike has been with the SCCA for 6 years now and it has always been a special experience for him, to say the least. “I originally started because it was a great place for my Dad and me to learn better car control, which in turn helped us become better drivers on the road”. Since then he has gained so many friends from all over the country and has had so many wonderful experiences. All his time with SCCA has really helped him gain experience in competitive driving, vehicle dynamics, and getting the privilege to drive FK03 and 04. With all his SCCA experience, as well as being a senior member of the team, he has the unique opportunity to design and set up the courses that we run for team test days in Orange lot. And when he’s not busy being the test day safety person he still gets to occasionally drive the formula car.

Jude Ward: 1995 Mazda Miata Kart

A Miata with the original 1.8L engine while getting as much weight savings as you can! All panels except the hood were removed to reduce weight all while maintaining the ability to drive it home on the street. Additionally, this Miata drove on full Avon slick racing tires, although a bit old, to get some additional grip on track. “A big thanks goes out to CKRSCCA member Dustin Libby for letting us send this machine through the corners at autocross!”

“SCCA has presented the team with many opportunities to not only test the Formula Car itself, but also our skills as drivers in personal vehicles.” Being able to run autocross through CKRSCCA has enabled Jude to gain a better idea of how competition will be, as well as gain experience through the ups and downs in his own driving skills. Not only does CKRSCCA affect his driving ability, but also the bonding between teammates on the team who have also gone through friendly competition and banter both before and after race day.

Billy Floyd: 1990 Mazda Miata 1.6 Liter

Billy’s love for SCCA materialized over the past few years, It all started with his friends always wanting him to go and autocross. After several years he warmed up to it. But what made him stick to it was the friends we made along the way to the finish line. His car is unique to him as he got it for himself for his high school graduation. He has done plenty of upgrades: rollbar, wheels, tires, plaid interior, and a custom exhaust. “For me personally SCCA has Impacted my life on Formula Kentucky. It helped me to begin to understand the basics of driving through the autocross experience. It has taught me to be humble. There's a lot to learn from this, It puts into perspective the physics behind a race car and how important vehicle dynamics is for driver feel.”

John Psyck: 2017 Ford Focus ST

John only recently started racing at his local SCCA chapter, but got hooked after his first event. “It’s a great opportunity to really drive my car hard, and the emphasis that autocross puts on tight cornering has made me feel much more confident and in-tune with my car.” The car that he drives at events also happens to be his daily driver, and his only form of transportation besides a motorcycle. It’s a modified example, but with no regards to a specific class of competition- something he plans on changing in the future.

As far as his relation between SCCA and the Formula SAE team goes, the autocross experience transitioned John very well from not racing at all, to being a primary driver for the racecar that we build here at the University of Kentucky. “It’s really amazing how similar the racing at competition is to what we have with our local chapter- and I look forward to getting all the practice I can get!”

Ethan Kammer: 1990 Mazda Miata (Co-Driver to Billy Floyd)

“For me SCCA is the thing that was able to fill a major hole in my life. Ever since I was little I have wanted to race something. I’ve raced go-karts, four wheelers, and even RC cars trying to find something that I enjoyed.” All of which he did but finally getting to race in a full size car is what he's always searched for. “The enjoyment you get from sending a stock miata through cones without a care is amazing and gives such a great feeling.”

For Ethan, he may not own the car but he thinks that’s what makes it even more special. It brought him closer with other people like himself and even better since it is fellow UK students and Formula Kentucky members. So they just all get to go do what we love with such a great community of people surrounding them.

Adam Reynolds: ‘95 Mazda Miata Kart (Co-Driver to Jude Ward)

“SCCA is a great way to meet more enthusiasts and hone your driving skills. It also lets you see a variety of different vehicles and platforms that people are passionate about!”

The Miata that Jude and Adam shared might not be powerful, but it’s extremely lightweight and has incredible grip from the racing slicks. SCCA has given Adam more time to hang out with his teammates and take a break from the sometimes stressful work of classes and FSAE.

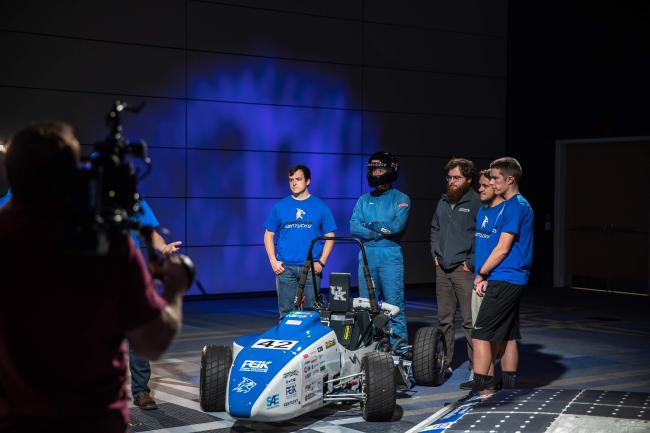

FK04 Competition Results

Recently, our new Team Captain Adam Reynolds had the chance to sit down with the College of Engineering’s media team and talk about the results from FSAE Michigan 2022! Check out the article they wrote here!

Our trip was full of success, knowledge growth, and setting up for the future. This has been the most documented competition in the team’s history, with our primary objective being to learn as much as possible. FK04 was an iteration zero car - one meant as a baseline for future development and testing. This foundation is very strong, and it showed at Michigan International Speedway last week! Below is a list of our event scores from Michigan May 2022:

Static Events:

Sales Presentation - 73/75 pts, 3rd place of 99 teams!

Cost Presentation - 84.7/100 pts, also 3rd place overall!

Design Judging - 80/150 pts, a 10 point increase from FK3.5!

Adam and Audrey with 3rd place in Sales Presentation, and Ashley and John J. with 3rd in Cost

Dynamic Events:

Acceleration - 47th

Autocross - 35th

Skidpad - 33rd

Efficiency - no points received

Endurance - DNF

FK04 during dynamic events, driven by Colton C, Ethan K, John P, and Michael S ...........

Overall Placement: 41st

During endurance, FK04 had a fuel leak from one of the injectors that had come unseated. This caused us to be black flagged after 1.5 laps. While this is certainly a disappointment, overall, competition was a massive success. We improved drastically over our 67th percentile finish in 2019, placed on the podium in two categories, beat several team records, and learned so much along the way that we can’t wait to bring to the future.

New Member Interest Meeting Spring 2022!

Calling all new members: Our Interest Meeting is coming soon! Join us January 18th at 8pm in White Hall 212 for a look at our club! Come see what we do and how you can join. Hope to see you there!

Spring New Member Garage Tour!

All prospective new members: We are holding a Garage Tour on Saturday, January 8th at 12PM! We'd love to see you there! We are located at the DV Terrell building, right behind Funkhouser.

Fall 2021 Newsletter

Dear Supporters and Alumni of Formula Kentucky,

Fall of 2021 has been an eventful semester so far! From new member recruitment to the increasing pace of manufacturing, our team has come together and worked hard to make this semester extremely productive.

This fall, while we are manufacturing, we’re asking our sponsors for input! We’d love to get feedback on what we’re doing, see how we can improve our design and manufacturing processes, and get to know your companies better. If you want to visit us or give any advice, feel free to email us so we can set something up!

FK04 Manufacturing Updates

Our team has made significant progress this semester towards the build of FK04. We have assembled a manufacturing timeline in Microsoft Project, and predict we will finish construction early in the spring semester, leaving us at least 1-2 months of testing time before competition in May 2022. FK04 is looking to be the most reliable and thoroughly tested FK vehicle in our team’s history.

Aerodynamics Subsystem

Our aerodynamics subsystem has been hard at work since the beginning of the semester both with recruitment and manufacturing. There are multiple new members on the team that have expressed interest in joining aerodynamics and have been showing initiative in showing up to workdays and helping out with our manufacturing. As aerodynamics started the semester with only two members, the extra hands from new members have been greatly appreciated as we continue to work on preparing molds to complete layups. We have encountered air leak issues on one of our fiberglass molds which has prevented us from completing that carbon fiber layup, but we have been troubleshooting and figuring out what steps to take to make progress. We have also begun assembling another set of foam molds for an additional piece of bodywork that we received, and our members have been hard at work assembling, sanding, and preparing that mold for the fiberglass stage. We will be sending off our last set of foam molds to be machined in the next few weeks, and anticipate completing a few more layups in the near future.

Business Subsystem

Business has had a great start to the year. Campus Ruckus and K week recruitment were very successful, and the team gained 30 new members this semester. FK101 has also been renewed this year with updated presentations with the goal of transferring knowledge to our new members. One of our new projects has been revitalizing our old YouTube channel. We have updated some graphics and posted recent videos, with plans to become more involved in posting regularly. We also completed our Wildcat Cage sponsorship presentation recently, from which we received $4,000 for additional manufacturing expenses, as well as team enrichment and safety equipment. Our new members have also started working on finding a new trailer for competition, as well as posting “Manufacturing Mondays”on our Instagram and Facebook, documenting weekly updates on the car’s progress. Overall, Business has had a busy and productive semester, all while documenting the progress of other subsystem’s manufacturing.

Chassis Subsystem

Chassis has been hard at work notching, assembling and grinding tubes into our jig to ensure that FK04’s frame is a close fit so we can prepare for tacking and welding. We did a lot of subsystem recruiting this semester so that we can get plenty of members to start learning and practicing welding in preparation of starting to weld the frame. We have also finished machining the rest of our frame jig pieces, so after plenty of tube fitting, we are finally starting to see the frame come together. Aside from the frame, we have also made lots of progress with the team’s first custom designed and manufactured steering wheel. This helps us fine-tune the ergonomics of the wheel, and gain experience with machining processes. Lastly, we have just started testing and practicing sewing various pieces of the headrest together so that the final piece has the best stitching and embroidering we can get.

Electronics Subsystem

Electronics is working on getting the pi dash working with sensors, and are also getting the RaceCapture app settings and screen organized now that the app is opened up. We have started back on manufacturing and testing one to two sensor boards per week, and we just finished the first prototype case for the sensor boards and are about to 3D print it. We’re also finishing up the design for the battery box and should be starting manufacturing soon.

Powertrain Subsystem

Powertrain has been working hard to finish up many individual components so that we are ready for our time with the car. Our differential brackets have finished being manufactured, as well as three out of four runner tubes have been completed. We have made progress on our gas tank and it is in the process of being welded. One area we have also been working to improve is our general knowledge of the parts we are using. We recently took apart our Drexler limited slip Differential and learned how to adjust it. By adjusting the three possible ramp angles, we can change the torque split between the rear wheels. Continuing to learn about parts like this helps our team members gain important knowledge and experience that will benefit us come competition in May. When competition drivers comment on issues regarding how the car is handling, Powertrain will be able to help accordingly. Our new members are currently working on reassembling our previous car, FK03. This project was designed with the intent to get them familiar with the assembly process, and allow them to get hands-on experience as preparation for making FK04. This would also allow us to have a running car for marketing and events.

Suspension Subsystem

With our team being back together in person, we’ve made lots of progress on fixing some of our problematic designs. Our spindles and uprights are in their final stages, with the spindles being 100% complete, and our uprights in the stages of simulation to verify that our design changes behave as expected. These will be sent off to an outsourced machinist to be completed. We are also utilizing 3D printing for rapid prototyping of part fitment. As far as new parts, our front and rear shock mounts are also in their final stages of completion, as we are beginning the initial simulation stages to see if we need to increase the thickness of any parts due to stress concentrations. Once these parts are out of our hands, we will be initiating our manufacturing process, where we will be cutting, welding, and machining some of the parts that don’t directly rely on anything else, like our control arms or rockers. We have made a ton of progress since we have returned to in-person, and we are very happy to say that we are getting back on track, and fast.

Fall 2021 Transition of Power

Chief Engineer: John Jay

Former Electronics Lead John Jay has stepped into our Chief Engineer Position. John is looking forward to overseeing the manufacturing of FK04, and implementing the usage of project management tools like Microsoft Project to keep us on track with our build schedule.

Campus Ruckus and New Member Garage Tour!

Calling all interested new members! Come check us out at Campus Ruckus on Thursday, August 19th from 8pm-12am, and take a tour of our garage and office on Saturday, August 21st at 11am! These are two great chances for prospective new members to get to know our team, our workspace, and our plans for the year!

Fall 2021 New Member Interest Meeting

Welcome back to campus! Our first meeting of the year, our New Member Interest Meeting, will be Tuesday, August 31st in White Hall 118 from 5-6 PM. Join our members Tuesday evening for our big kickoff event! We welcome all majors and grade levels, and we'll have our leads and team captain there to discuss what it means to be on the team. We'll go over the upcoming Formula SAE season, normal club expectations, goals and highlights as well as any questions you might have. If you wish to attend the event please feel free to contact our Business Lead or Team Captain. We can't wait to see you there!

Spring 21' New Members!

Interested Members! We are still accepting engineering majors for the spring semester until March 10th and all other majors are open to join anytime! Stop by our meeting (or join virtually) to check us out. See our 'Join Our Team' tab for more information!

Spring 21' Interest Meeting

Wednesday Feburary 10th, Whitehall room 118 from 7-8pm. Join our members Wednesday evening for our big kickoff event! Welcome to all majors and grade levels, we will have our leads and team captain discussing what it means to be on the team. We will discuss the upcoming formula SAE season, normal club expectations, goals and highlights as well as any questions you might have. We have a virtual option for this event, if you wish to attend the event please contact our business lead or team captain for our RSVP link as there is a limit for those who can attend. For the virtual zoom link reach out to the same people! We hope to see you there! GO CATS! https://uky.zoom.us/j/441174322

Design Freeze

On October 25th our team reached our design freeze for our new car FK04. This deadline represents the compeltion of all our desings and models for the car. The following two weeks have consisted of reviews and discussions to fine tune everything. Starting today we begin manufacturing FK04. Working through winter break our projected end date is March 7th before we begin test driving. Stay up to date with our newsletters by emailing FormulaKentucky@Gmail.com to request to join our mailing list OR follow us on facebook & Instagram @FormulaKentucky

New Member Interest Meeting

Thursday, August 27th! 6-7pm in WhiteHall 106! Join our members Thursday evening for our big kickoff event! Welcome to all majors and grade levels, we will have our leads and team captain discussing what it means to be on the team. We will discuss the upcoming formula SAE season, normal club expectations, goals and highlights as well as any questions you might have. We have a virtual option for this event, if you wish to attend the event please contact our business lead or team captain for our RSVP link as there is a limit for those who can attend. For the virtual zoom link reach out to the same people! We hope to see you there! GO CATS!

k-week and campus ruckus!

Hey wildcats! Welcome back to campus! Our team will be at campus ruckus on Friday August 14th from 4-9! Stop by and say hi! We are also hosting a shop tour Saturday August 15th from 1-1:30 during k week! Feel free to come to either so you can meet our team and see our car!

E-Day 2020

Engineering Day is hosted every year by the College of Enginnering at the University of Kentucky. For the past 5 years we have been inivited to talk about our club and show off our car. This year was no diffrent as we brought out FK03 and were able to have young children sit in the car and then we started it up for the crowd to hear. It was overall a very succesful day and we look forward to doing it again next year.

Spring Test Days

The first test day of the semester took place on 15th of February. The team got several hours of testing in and the car ran with minimal troubles. We were able to reward four of our hardest working members with seat time in FK03. Unfortunately, the day ended prematurely when the rear chassis bar bent due to fatigue and improper support. This issue was fixed with further reinforcement of the rear chassis member thanks to some very hard work from our Chassis Subsystem members.

On march 1st we held our most extensive test day to date with an estimated 25 miles on the car in a single day. We faced no major mechanical issues and gathered a lot of good information from the car. The only issue we faced was overheating, which we are attempting to remedy by testing different radiator setups. Overall, our spring testing is going phenomenally thus far.

Our last test day before spring break is on March 8th to test four different

radiators.

Formula SAE/Formula Student World Rankings

Each year Formula Student compiles a World Ranking for Formula SAE teams based on the teams improvement from the previous year, their performance in the competition(s) they attended that year, and the level of competition faced at the competition(s). We attended FSAE Michigan in 2017 and placed in the 80's out of 120 teams. Then Formula Kentucky attended Formula SAE Lincoln in 2018 and placed well enough to earn ourselves a 296 world ranking out of 614 teams considered. After our successes at FSAE Michigan in 2019, however, we jumped in the World Rankings to our best ranking in team history. With a world ranking score of 272.5183 averaged over the last three years of competition where we scored 217.8, 283.4, and 301.6 respectively Formula Kentucky is officially the 292nd ranked team in the world of the 614 teams. This scoring is good enough to move us to a ranking of 92nd of 151 United States based teams in the competition. We are a younger team than a lot of the competitoon in the US, so a 92/151 ranking is admirable, but we are striving to increase our ranking in the competition seasons to come.

Engineering Live

Just before we left for Thanksgiving Break, we were given the privilege of showcasing the fruits of our labor on the University of Kentucky College of Engineering's live podcast, Engineering Live. Engineering Live allows current and potential students to learn more about the CoEng and everything it has to offer. We displayed our last competition car, FK3.5, in the Gatton Student Center Ballroom alongside the current UK Solar Car and when the podcast went live our captain and a few members were on screen representing the team. We answered questions about the history of the team, the history of the car, and the benefits of participating in Formula SAE. You can see our portion of the broadcast here: Formula Kentucky Engineering Live We are very grateful to the UK College of Engineering for the opportunity and we look forward to working together for similar events in the future.