March 7, 2025

February 2025 Newsletter

Dear Supporters and Alumni of Formula Kentucky,

As we begin our spring semester the team is working hard on the manufacturing process to get the car ready for competition in May. Across the board, the subsystems have been putting in a lot of hard work and time as we begin to approach the testing period. As always we are very grateful to all of our sponsors who make this possible.

We are excited to see the car come together and we can't wait to see the FK07 in its final form. As always thank you for your support!

Chassis

Chassis received the frame from VR3, who notch bends and cuts the tube frame to save hours of work in the shop. The frame was then laid out in the jig and tacked together before the entire welding process began. The welding of the frame was finished right before Christmas break. Currently, Chassis has begun placing all other needed tabs to install various components in the car. Other projects are awaiting parts arrival and will be built and installed once they arrive.

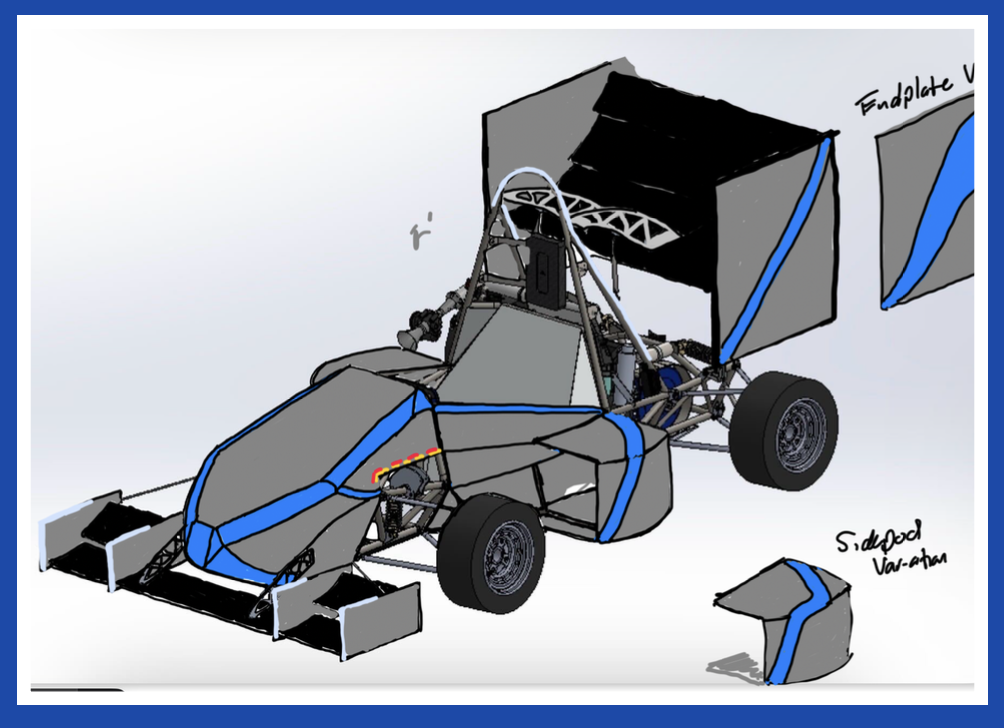

Aerodynamics

Since October, Aerodynamics has constructed the foam molds using the Shopbot machine to create the shapes for the carbon fiber layups. These were completed in the middle of January and will go through post-processing before being mounted to the car. They have also completed their first resin infusion layup since 2022 on the first of the two side pods. The team is in the process of designing livery ideas for the car including one that will mimic the DeLorean from Back to the Future.

Electronics

Electronics has been working on developing the wiring harness, specifically with integrating the new telemetry system. Thanks to the Bosch Motorsports sponsorship the team has gotten their C70 datalogger along with three WinDarab seats, which has been used to make great strides in data collection and data analytics. Moving into manufacturing, they are looking forward to fabricating the main wiring harness as well as the breakout harness for the C70. The plan for the breakout harness is to make it completely motorsport spec, which will make it extremely durable and useful for years to come.

Powertrain

Since October, the Powertrain subsystem has been spending their time tearing down the engine from FK06 and refreshing the engine for FK07. They have been working on the installation of the radiator as well as the installation of the motor mount. There has also been finalization work on the oil pan gasket. Looking towards the future there has been work done on development for projects including an external fuel pump setup.

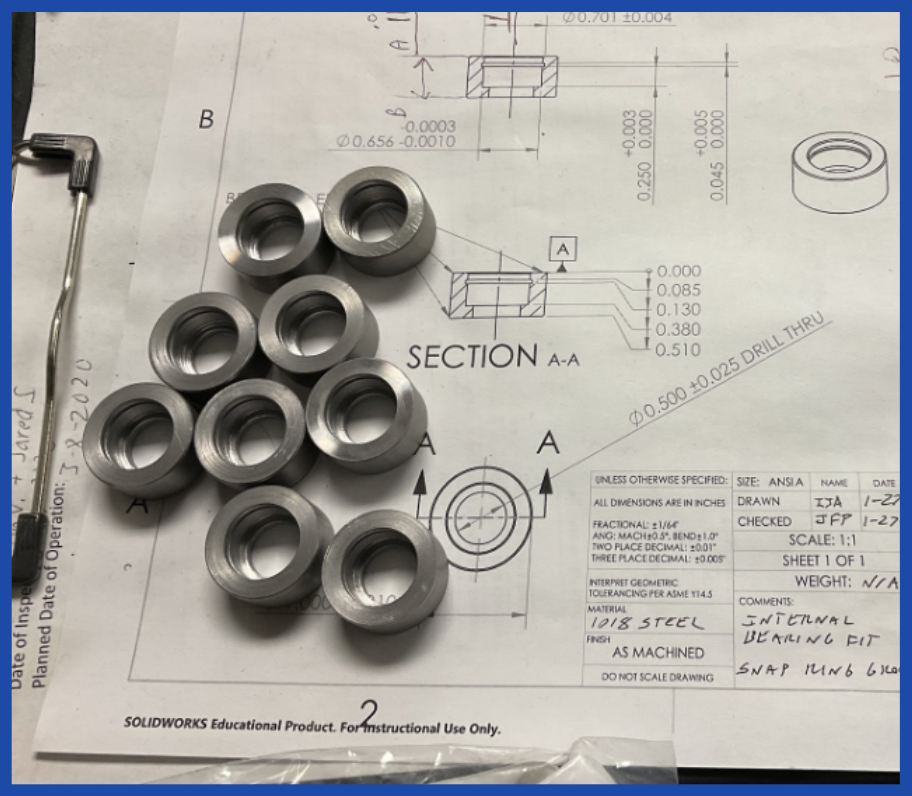

Suspension

Since October, Suspension has been hard at work getting various parts machined for assembly. This includes such parts as the spherical bearing housing shown in the picture. Right now all of those parts are coming together and the entire suspension will begin to be built in the upcoming weeks.